Technology-Innovation-English

MG is recognized by suppliers worldwide as "Interlligent Trading Farm"

in the natural sausage casing trade.

We believe that this is the result of accumulation of collective expertise

acquired by meeting challenges through intellectual approach.

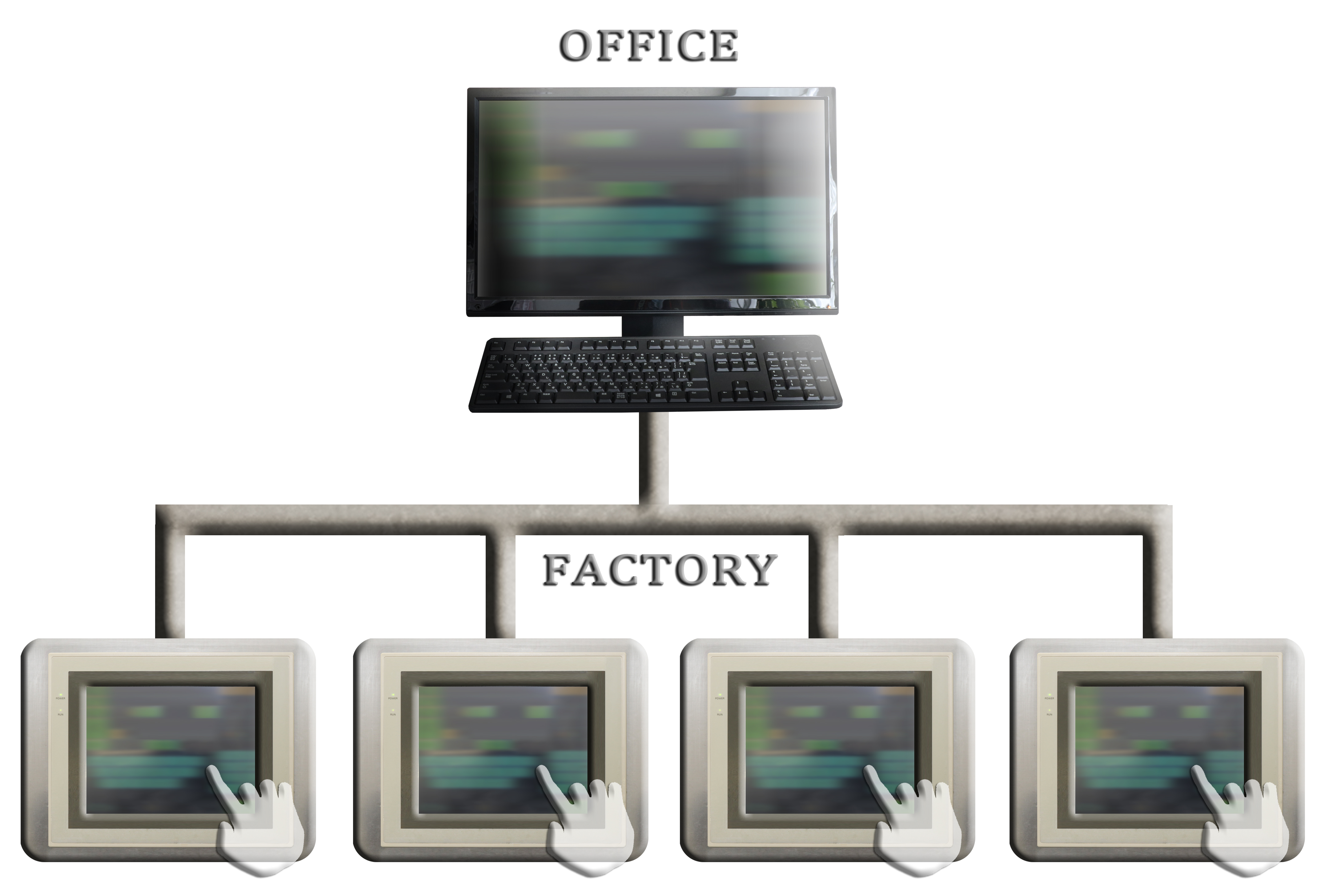

MIS is an inspection system of which we are proud, we have over thirty items of Matsunaga original check points which are highly esteemed in Europe.

MIS integrates detailed data input by highly skilled inspectors and reforms it into a database easliy understandable to anyone.

This makes it possible to share the input internally at any time, thereby playing an important role in quality control.

Our inspection system was introduced audience in the 34th Annual Meeting of International Natural Sausage Casing Association (INSCA) on the 22th May in 1999 and it was admired as an effective means of quality control.

This makes it possible to share the input internally at any time, thereby playing an important role in quality control.

Our inspection system was introduced audience in the 34th Annual Meeting of International Natural Sausage Casing Association (INSCA) on the 22th May in 1999 and it was admired as an effective means of quality control.

Through innovative means, we constantly try to consider casings from various

points of view.

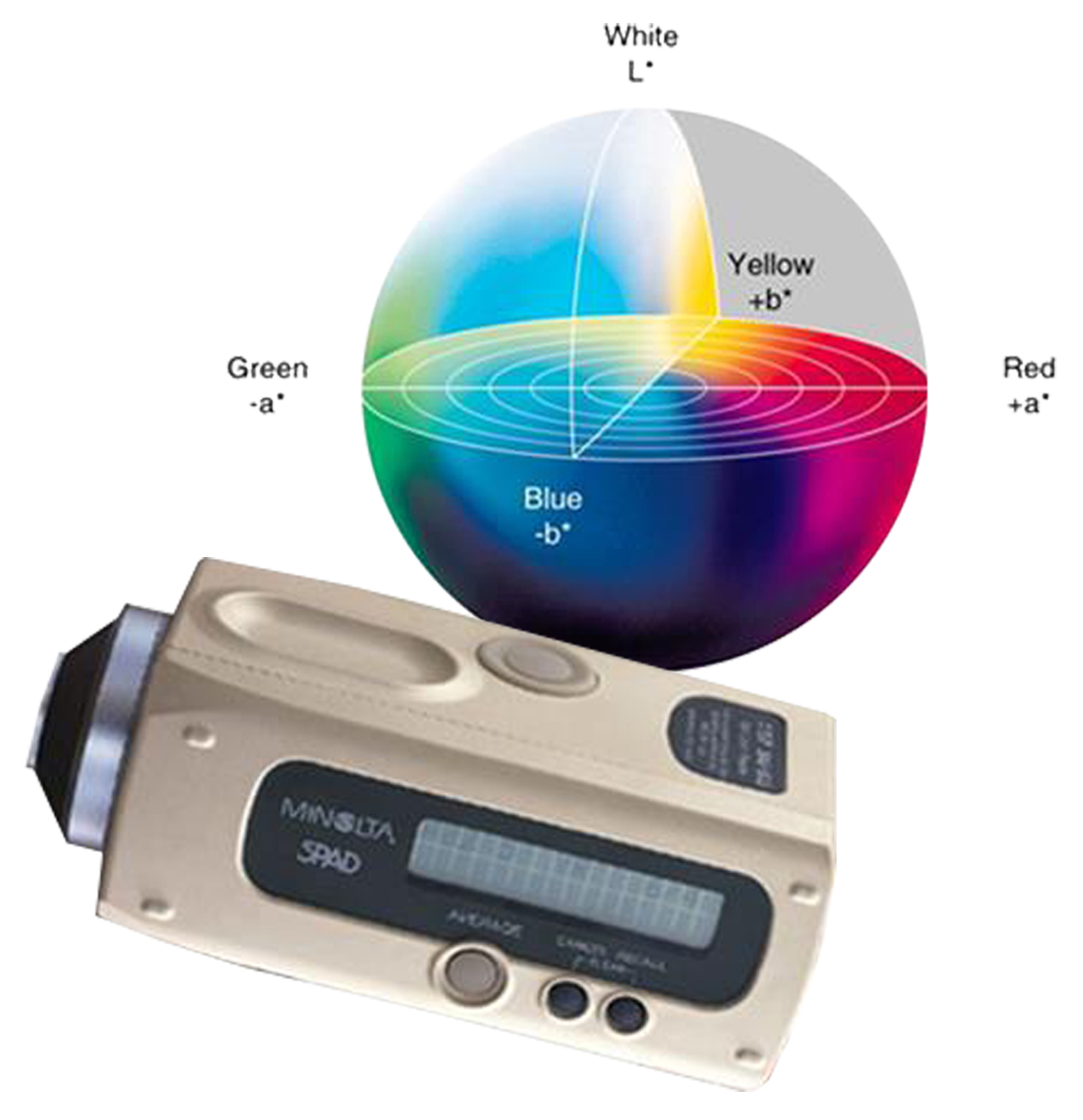

○Measurement of the color

By using colorimeter, we measure the color of sausage products to check the effect of smoke intensity.

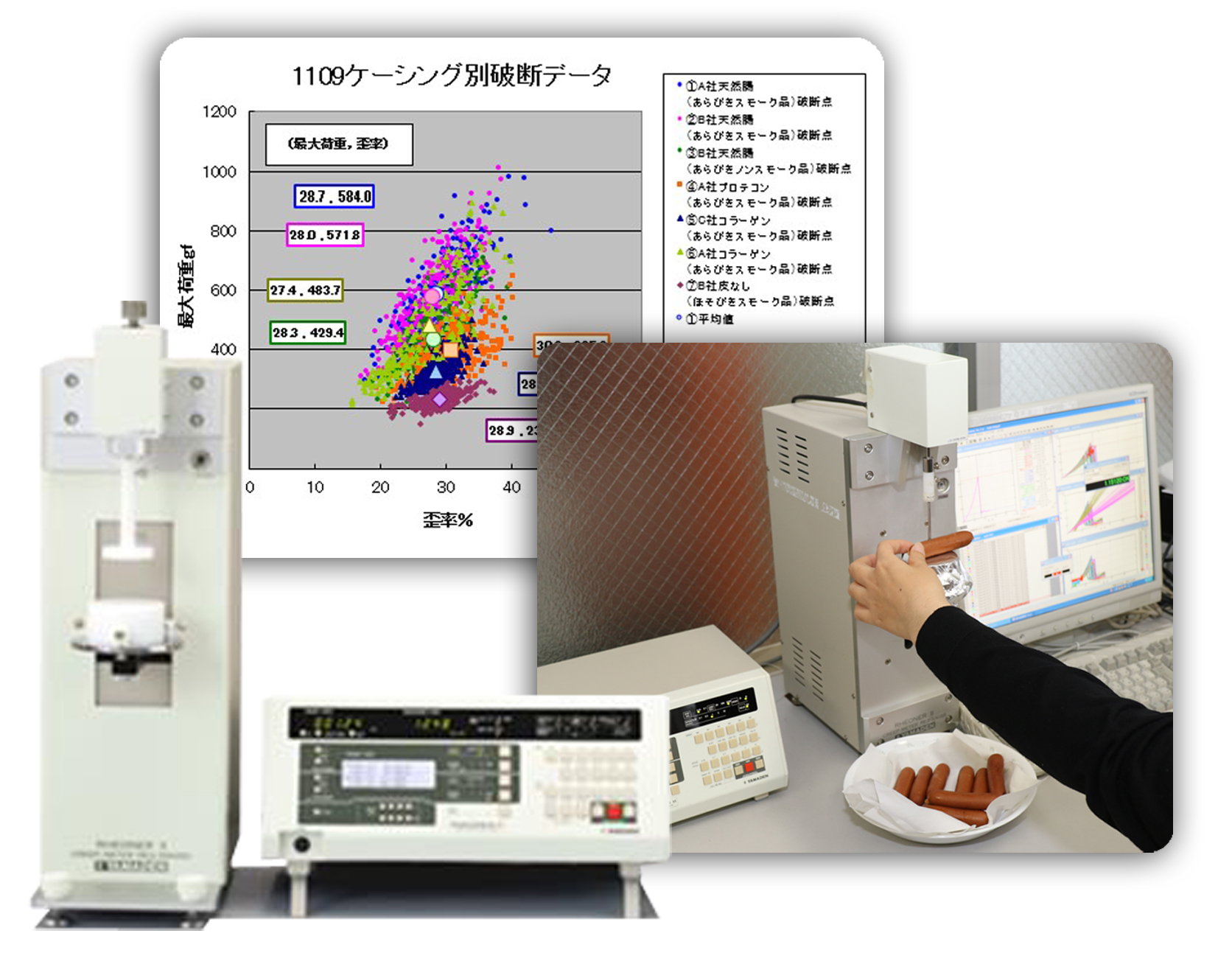

○Measurement of the hardness.

By using a strength tester, we measure the hardness of sausage products to check the texture.

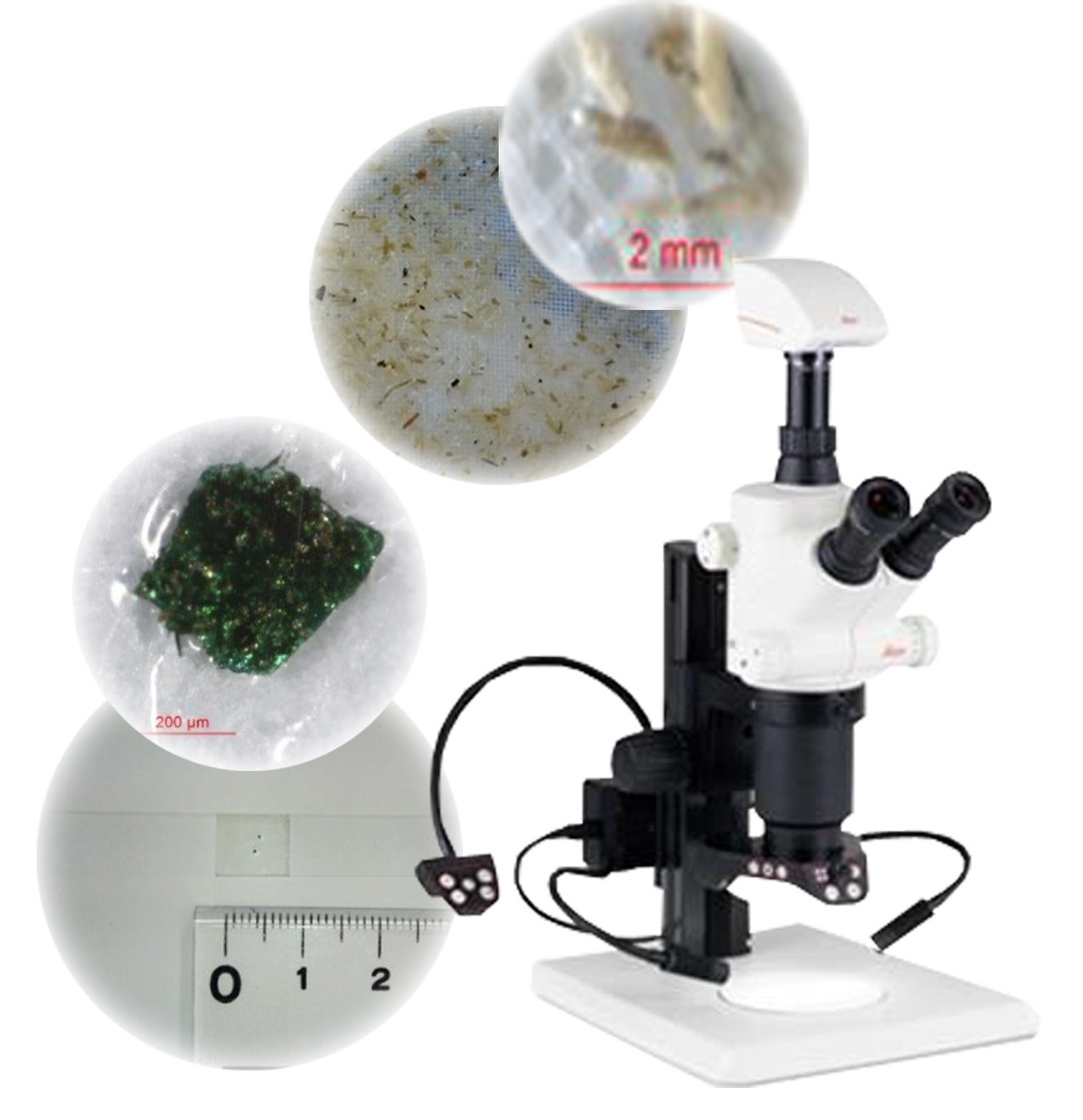

○Investigation of causes

By using an optical microscope, where necessary we magnify foreign objects on the casing from 10 to 100 times.This reveals sources of contamination, and resolves problems before they occur.

バナースペース

Matsunaga Group

2507 Niizo, Toda-Shi,

Saitama 335-0021 JAPAN

TEL:+81(0)48 433 7070

FAX:+81(0)48 433 6359